Subtotal: $59.99

PerformancePro Artesian2 Variable Speed High Flow Pumps

Price range: $1,319.50 through $1,732.50

- Quiet, Self-Priming, External Variable Speed Pond Pump

- Professional-Grade External Water Pump, Made in USA

- Low Energy Consumption, Reliable Design for Continuous Operation

- 2″ Unions Are Included With 1.65 HP or 2.7 HP High Flow Oil-Free Motor

| Stock | type | Price | |

|---|---|---|---|

| A2-1.6N-HF-DAF Artesian2 Dial-a-Flow High Flow | $1,319.50 | ||

| A2-2.7N-HF-DAF Artesian2 Dial-a-Flow High Flow | $1,732.50 |

Description

Product Details

PerformancePro Artesian2 Dial-A-Flow High Flow Pumps provide the flexibility of an adjustable flow rate while handling large volumes of water in fresh and salt water applications. The Artesian2 Dial-A-Flow High Flow Pump Series offers an excellent blend of durability, power, and energy efficiency. Designed for longevity, these rugged units feature corrosion and abrasion-resistant components, a stainless steel shaft seal, an integrated strainer pot, and self-priming convenience.

PerformancePro oil-free 230V external pumps are designed for continuous, quiet operation and long-term reliability. Each unit comes with convenient and easy-to-use 2″ union fittings. These high-flow pumps do not include an electrical cord, and we recommend having them hard-wired by a qualified electrician. Choose from two models: the 1.65 HP pump, with a maximum flow rate of 9,600 GPH and a max head height of 50.8 feet, or the 2.7 HP pump, with a maximum flow rate of 12,780 GPH and a max head height of 54 feet. Salt water kits are available for both models.

Tech Specs

9,600 GPH

|

12,780 GPH

|

|

|---|---|---|

| Dial-A-Flow Pump Series | Artesian2, High Flow | Artesian2, High Flow |

| Model Number | A2-1.6-HF-DAF | A2-2.7-HF-DAF |

| External Pump Use | Out of Water | Out of Water |

| Application | Fresh Water or Salt Water* | Fresh Water or Salt Water* |

| Approx. Dimensions | 25.82″L x 11.25″W x 13.50″H | 25.82″L x 11.25″W x 13.50″H |

| Oil-Free Motor Type | Self-Priming Centrifugal | Self-Priming Centrifugal |

| Electric Motor Enclosure | Totally Enclosed Fan-Cooled (TEFC) | Totally Enclosed Fan-Cooled (TEFC) |

| Intake & Discharge Ports | 2″ Ports w/ 2″ Unions Included | 2″ Ports w/ 2″ Unions Included |

| Total Horse Power (THP) | 1.65 HP | 2.7 HP |

| Max Flow Rate | 9,600 GPH | 12,780 GPH |

| Max Head Pressure | 50.8 Feet | 54 Feet |

| Frequency | Variable | Variable |

| Speed (Revolutions per Minute) | 3,450 RPM | 3,450 RPM |

| Volts/Phase | 230/1/60 | 230/1/60 |

| Max Amps | 6.45 (@230V) | 10.3 (@230V) |

| Max Watts | 1,480-Watts | 2,300-Watts |

| Power Cord Length | No Cord | No Cord |

| Warranty | 3-Year Fresh Water Applications 1-Year Salt Water Applications |

3-Year Fresh Water Applications 1-Year Salt Water Applications |

*Salt water kits are available at the time of pump purchase and are recommended for hard water, brackish or salt water.

How It Works

PerformancePro Variable Speed Pumps should be installed in a dry environment by a qualified electrician. This external pump is built with an electric motor that utilizes centrifugal force to generate water flow that travels into the strainer pot, filtering out debris.

Self-Priming

PerformancePro Dial-A-Flow Series Pumps are self-priming pumps, meaning it primes and operates at varying heights up to 9 feet above the water source surface as well as varying horizontal lengths.

If after starting the pump you notice it takes more than 3 minutes for water to start flowing into the priming pot after being filled with water and energized, it is recommended to install a rubber flapper type swing check valve. The valve should be as low and as close to your source water as possible to maintain constant pressure and shorten prime time.

The best location can even be underwater when possible as this can provide an air tight fit even without PVC adhesive. Some swing check valves have true union connection fittings that offer easier access for cleaning when needed. Never use a spring loaded check valve as it will reduce or stop flow.

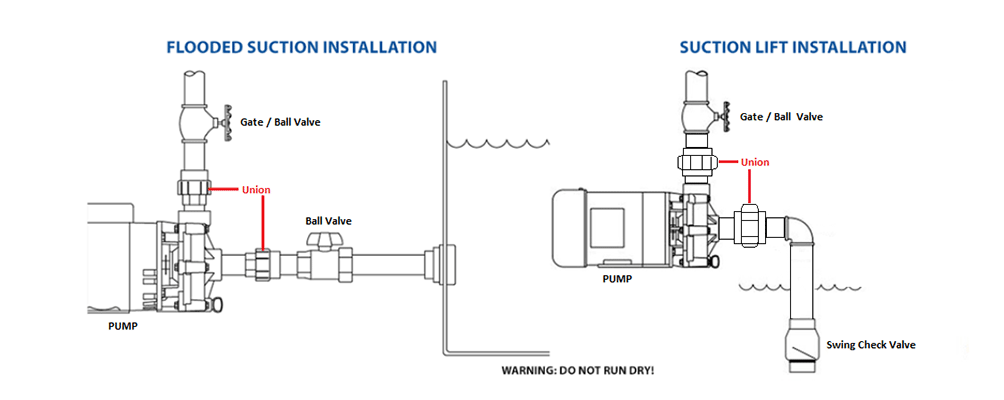

Installation Guide

Place the pump low and near the water source to prime quickly and achieve optimal performance.

Flooded Suction

• Ideal setup as it does not require priming.

• Ball Valve installed before and after the pump for ease of maintenance.

If the water source is higher than the pump, opening the supply valve will fill the pump with water. This applies to flooded suction systems. We recommend opening the strainer pot lid on both flooded and non-flooded systems.

Add water and clean the lid O-ring. Finally, close the lid tightly before starting.

Once you fill the priming pot and open the supply valves (if present), your pump is ready to prime. Turn the motor on by plugging in the unit or switching on the power supply.

Priming will vary in length. Water should continue flowing into the basket as the pump passes the priming process. The priming process should not take longer than 15 minutes.

The pump should never run dry. If the water stops flowing into the strainer pot, shut the pump off immediately and see the manual for Troubleshooting Tips.

When you start the pump, the water level in the housing should decrease rapidly. Only a small amount of water should enter the pump within 3 minutes. There is no need to be alarmed as this is normal. If no air leaks, the water flow will slowly increase, and the pump will work at its best.

Suction Lift

• Suction lift can be installed with a Swing Check Valve.

• Check Valve installation is recommended below water level to avoid dry running unit and aids in priming.

The pump ports are 2” slip on both the inlet and discharge ports. The 2″ fittings included with your pump should connect to PVC or flex pipe plumbing.

All plumbing lines should be self-supported and properly aligned. This will prevent undue stress on the housing and fittings. We recommend using a good primer and PVC cement to glue the pipe to the tailpiece fittings.

To stop back-flow or reverse rotation, use a ball or swing check valve when the pump is below water level. A ball valve will supplement a swing check valve and allow flow adjustments.

FILL THE PRIMING POT WITH WATER BEFORE STARTING THE PUMP.

Be sure your installation location is no higher than 9 feet above the water surface level. We recommend using a 3″ tube.

It is best to avoid adding too many fittings or strainers. This will prevent the water flow from slowing down and the pump from taking longer to start. Refer to the Pump Operation information in the manual.

When determining pump placement, it is important to consider the distance and height from the water source. Place the pump no more than 9 feet above the water source to ensure a good prime time. Positioning is also important to maintain the pump’s ability to stay primed and minimize cavitation.

Pump Maintenance

The strainer basket in the priming pot should be inspected and cleaned at least one (1) time per week, more often if excessive debris is present in the operating environment. Also look for any leaks between the motor and pump housing is present, replace the mechanical seal.

Winterization

In freezing environments it is advisable to winterize your pump to prevent damage. Do not allow pump or system plumbing to freeze, as freezing can cause damage that may lead to equipment failure.

How to Read a Water Pump Flow Chart

The Flow Chart below is designed to allow you to plot your pond’s water-flow requirements, and easily determine which pond pump will meet those requirements.

Start by calculating your pond’s specific water-flow requirements, measured by Head Pressure (Feet) and Gallons Per Hour (GPH) water flow.

Flow Charts

Aim for the Middle of the Curve:

After plotting your calculation on the Flow Chart, find a pump that falls in the middle third of the pump curve, not too close to either axis. Pumps that fall on the fringes of the curve will not work as efficiently for your application, and they will be pushed to their operating limits, reducing their life span.

Other Considerations When Choosing a Pump:

It’s Better to Oversize than Undersize: You are better to slightly oversize a pump than to undersize. When oversizing, you can always install a ball valve to reduce the water down to your desired flow.

Check Your Other Equipment: Choose a pump that does not exceed the indicated maximum flow rate on your filter or water feature. Also, be sure the tubing you select can handle the flow rate of your pump.

Additional information

| type | A2-1.6N-HF-DAF Artesian2 Dial-a-Flow High Flow, A2-2.7N-HF-DAF Artesian2 Dial-a-Flow High Flow |

|---|

Aquascape Signature Series 8.0 Pond Skimmer Weir Plate Assembly (MPN 29056)

Aquascape Signature Series 8.0 Pond Skimmer Weir Plate Assembly (MPN 29056)